I know, might be a bit overkill, but that’s the good life.

I know, might be a bit overkill, but that’s the good life.

https://www.youtube.com/watch?v=dTcvmmOkqJI?t=17s

Now that Maximum Baby is crawling I wanted to get our huge tv off of the rickety cart it was sitting on. Sam had a tv fall on her as a child and one is enough for us.

The tricky thing here is that we wanted to mount the TV on a concrete pillar.

Trying to attach a flat thing to a curved thing is tricky. My solution was this:

Using a friction mount is a dicey thing. Materials have two kinds of stickiness – or friction coefficients. One is how sticky two things are when they are at rest (static friction coefficient) and the other is how sticky two things are when they are moving (kinetic friction coefficient). Friction works great right up until you overcome the static friction coefficient and then it works very poorly because the kinetic friction coefficient is always lower than the static friction coefficient.

Good news is we can calculate how much force our friction mount should support! Friction is dependent on the pressure between two surfaces (the normal force) and the stickiness between them (the friction coefficient). The frictive force is going to be our normal force times the static friction coefficient.

How much normal force do we have? I’m estimating that I can ratchet around 150lbs of pressure on one of those ratchet straps. Let’s cut that a little bit because I haven’t been working out and I am an optimist. Let’s call it 120lbs. I’m using 3 ratchet straps so that adds up to 360lbs of pressure.

There’s a table on that page with friction coefficients for common materials. Looks like they say the static friction coefficient between wood and concrete is 0.62. 360lbs * 0.62 = 223.2lbs.

I’m around 175lbs – I should be able to do a pullup on this!

And I CAN!

My TV weighs 50.8 lbs, the tv mount weighs 8lbs, my shelves weigh 11lbs and they can support 22 lbs per shelf. I forget how much my soundbar weighs. Let’s call it 10 lbs.

50.8 + 8 + 11 + 22 + 22 + 10 = 123.8 lbs. I’ve got around 99 lbs of spare capacity before we hit the limit of my static coefficient of friction!

I feel like I can trust this not to drop on Max for a while! How long until Max might hang off of this and make it drop? Hmmm – when is he likely to be around 100lbs? Wolfram Alpha tells me a 10 year old American is around 94lbs. I should be able to teach him not to do it by then or get another ratchet strap.

Secret Project B has been so on my mind that I totally forgot to write up my Secret Project D!

Sam had been talking about wanting a dresser, but none of the ones we found really fit where we wanted to put one. We liked West Elm’s Hudson dresser. Clean modern style, but it was too deep to fit our space. Sounds like a job for me!

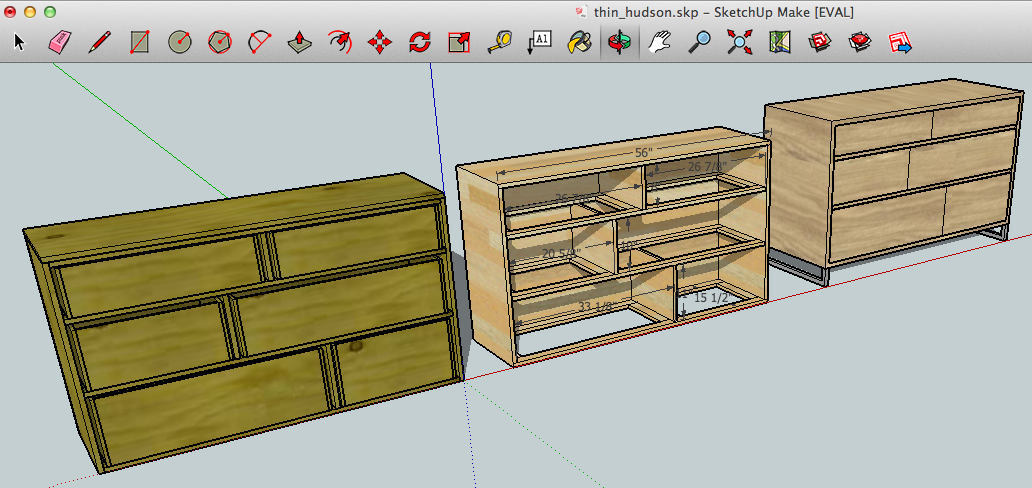

I made measurements and decided that the best way for a nerd like me to proceed would be to make a sketchup design. I found a sketchup model of the thin hudson and made my dresser model based on that.

I started working on this last August on nights and weekends.

Afterwards, I dropped by a West Elm to see how they put theirs together. That’s when I realized that I didn’t have to make the stretchers in the carcass solid – I could make them a frame and they’d be just fine. Also – less weight in the furniture will be helpful when we move it around.

Then life gets in the way – the project was on hold for months. After figuring out what I wanted to do I bought tools, and got started in December.

I decided to go with a furniture grade plywood. Not all plywood is crappy – some looks really nice. I went with Baltic Birch. It’s good looking, the beveled edges on the drawers have a sweet pinstripe on them and I could get it nearby at the Brooklyn Dyke’s Lumber1.

Plywood has a couple of other sweet properties for small apartment woodworking. The cross-grain layering of plywood makes it very stable with regard to moisture. This means I don’t have to have a jointer or planer to flatten the wood. In addition, the sheet of plywood has a continuous grain veneer – so you cutting the drawer fronts from one sheet of plywood preserves that grain across the drawers.

When you buy lumber, you have to know how to order it, and you need to know how much you want. The sales folks are used to dealing with people who order very large amounts, so not knowing makes you an irritant. You won’t get what you need. Fortunately, if you build your model in Sketchup first, there’s a handy plugin that calculates how much lumber to buy and gives you a cutlist based on your model. It even gives you a plan on how to get the most out of the wood with the least waste. That’s so helpful!

Armed with my cutlist, I grabbed a truck from zipcar and brought back three huge 4’x4′ sheets back to my woodshop in the sky.

After many nights and weekends of cutting, swearing, panicking, gluing, screwing, sanding and shellacing I got the dresser done. My woodshop in the sky has turned into a baby room, so I’ll have to find a new place to make any future furniture. If any folks are interested in either how I made it or what I’ve learned about small apartment woodworking, I could write more about that.